DEFINE YOUR KITCHEN CABINET STYLE

Already Know What You Want To Purchase? Start Shopping For Your Dream Kitchen Now!

Top 10 Characteristics of Our High Quality Kitchen Cabinets

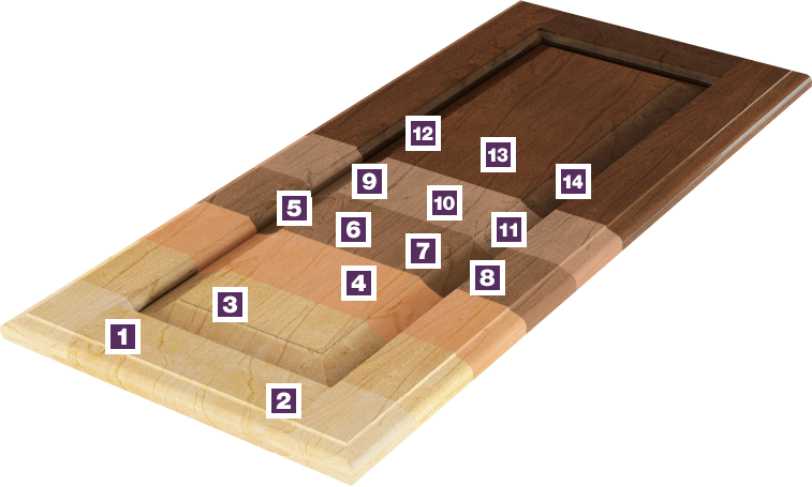

SHERWIN-WILLIAMS 14-Step Finishing Process

All of our wood doors and drawer fronts receive SHERWIN-WILLIAMS’s 14-step finishing process, resulting in one of the finest finishes in the industry. From the initial sanding to the final finish application, each piece of cabinetry is made to your exact specifications by our skilled craftsmen.

All-plywood construction

Cabinet boxes are typically built of plywood. The most robust cabinets have full plywood sides and backs to stay square during delivery and installation, handle the weight of heavy countertops, and resist damage from moisture.

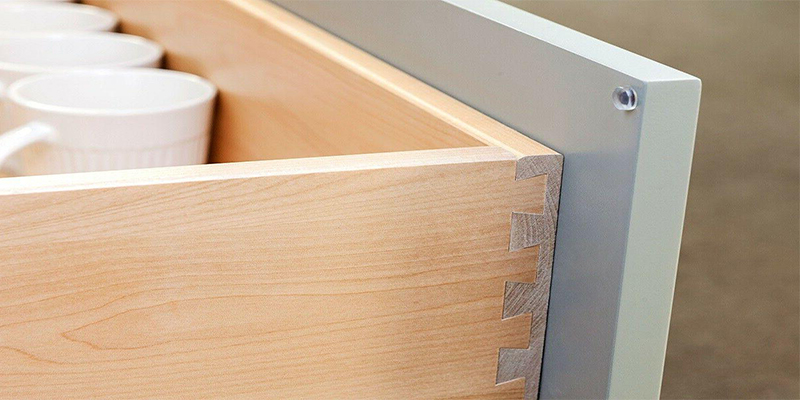

Dovetail Construction

All of our kitchen cabinets are required use of dovetail construction. A process that involves plywood side panels to perfectly interlock with a solid wood face frame through corresponding dovetail grooves. This highly resilient technique introduced to the market guarantees that cabinet lines are secure, strong, and long-lasting.

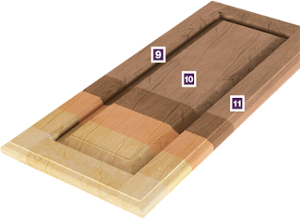

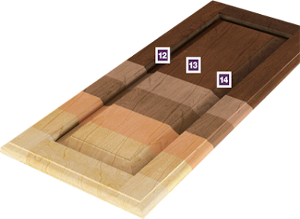

Anti-Warp Structures

The anti-warp component involves the use of plywood panels comprised of rigid reinforcement beams. By applying the beams with a dovetail construction technique to secure all components, our cabinet meets this standard ensuring a strong, reliable build that is resistant to distortion.

Corner Blocks

To ensure a unified and organic design build, our kitchen cabinet lines with plastic corner blocks, which keep the purity of cohesive construction.

Treated & Finished Cabinet Interiors

Treated and finished cabinet interiors are another significant feature of our kitchen cabinets as they produce a clear statement of quality and attention to detail. As opposed to manufacturing with an applied lining, Our vigorous top treatment techniques create a refined and durable design that is free of bubbling, peeling and chipping.

Solid Back Builds

For superior structural longevity, the back of a cabinet is constructed from one piece of solid half-inch plywood. Our cabinet backs with a strong and single piece of plywood to ensure durable strength and dimensional stability.

Soft-Closing Hinges

Our cabinet use of compact hinges with built-in, soft-close mechanism providing an impeccably gentle and fluid cabinet function.

Full-Extension Soft Closing Drawer Glides

The smooth full-extension soft-closing technology glides guarantee an enhanced running action that maximizes a cabinet’s storage to its full capacity, precisely utilizing space while also preventing damage and depreciation.

Drawer Face

To ensure proper door alignment and function, kitchen cabinet requires an effortless system utilizing a degree of mechanical precision for installing perfectly positioned drawer faces. We innovates with a unique technique using circular discs that allow for easy 3/8” adjustments in any direction, resulting in a cabinet that achieves an aesthetically graceful balance.

STEP 01

Kitchen Cabinet Mall selects quality wood,which skilled craftsman sand to a smooth finish.

STEP 02

After sanding,all surfaces are vacuumed to eliminate dust particles.

STEP 03

Craftsman hand-apply distressing,vintage and burnished techniques to selected finishes.

STEP 04

Equalizer stains are applied to balance the base color of the wood.

STEP 05

Toner is applied which establishes consistent color uniformity.

STEP 06

A deep penetrating stain is(hand-applied/hand-sprayed/applied)to reveal the wood grain.

STEP 07

All stained surfaces are evenly hand-rubbed and wiped clean of excess stain.

STEP 08

After slowly air drying,highlights,glaze,glaze details,burnishing stain,and vintage patina are hand-applied to selected finishes.

STEP 09

Specially formulated wood sealer is applied,penetrating all exposed wood surfaces for uniform protection.

STEP 10

Sealed product is placed in high-temperature oven to ensure a thorough cure.

STEP 11

All surfaces are hand-sanded again,providing a smooth,consistent surface to accept topcoat.

STEP 12

Environmentally safe topcoat is applied to maximize resistance to scuffing,dents,moisture,UV fade and household chemicals or agents. n.

STEP 13

Top-coated pieces are slow-cured in a 150-degree oven,creating a smooth,baked on surface.

STEP 14

Each cabinet is inspected and hand-polished,assuring quality and durability.

Secure Payments By PayPal

NO PAYPAL ACCOUNT NEEDED !

PayPal Buyer Protection ensures you get what you pay for.

If you don't receive the kitchen cabinets that you ordered, you may qualify for Paypal Purchase Protection, and Paypal will reimburse you for the full purchase price plus any original shipping costs, subject to terms and limitations.